Wheel bearings are developed to advertise reliable wheel turning however can similarly become frustrating on a long drive when they choose to fall short. So here is what can fail and also exactly how to tackle repairing them

Wheel bearings play a crucial duty within the drivetrain of any kind of vehicle, as they offer the initial connection in between the moving and fixed locations of the vehicle. A bearing– in its most basic form– is a friction decrease tool positioned within something like a wheel to assist efficiency of rotation. This is achieved as rolling generates much less friction pressure than sliding.

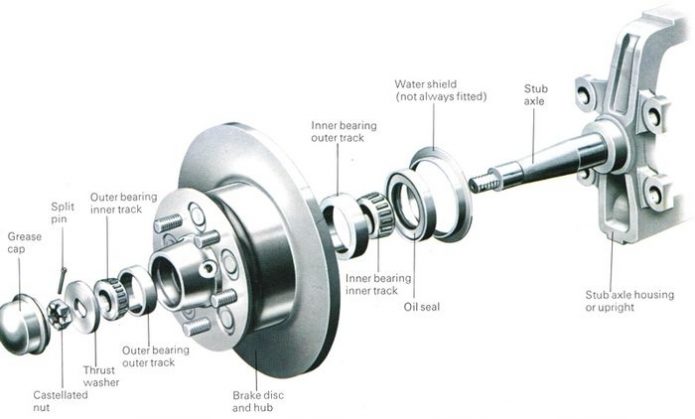

An auto’s wheel bearing does this by using little metal balls that roll between 2 smooth rings of metal. Along with grease, the bearing turns in-tandem with the wheel’s rotation, the rolling activity of the balls enabling the wheel center to rotate as easily as possible.

The wheel bearing is housed within the hub assembly, providing the static link with the hub carrier via an outer ring or ‘racer’. The driveshaft takes a trip from the transmission and also goes through the centre of the wheel bearing via the inner ring, developing the rotational collaboration. Roller bearings are made use of normally on the driven wheels of a vehicle, while conical bearings are mainly made use of on the non-driven wheels.

Like all mechanical parts on a cars and truck that turn, rub and roll, they tend to wear out. As well as the tell-tale sign of a wheel bearing that’s had its day is a consistent drone or hum from whichever wheel is impacted at different speeds. There are 3 basic reasons for a dodgy bearing:

- Incorrect positioning due to bad installation

- A harmed or leaking birthing seal

- An inward collision due to a side impact

One of the most usual mechanical failing is due to a seal leakage, which permits the lubricating grease to leave the bearing, and water and grit managing to worm its way in. This all total up to the destruction of the rounds as well as the external as well as internal real estate of the bearing, often developing that sandy, skimming sound as the wheel is turning. Looking inside a damaged bearing, there will often be tiny specs of metal that have actually broken off from inside the bearing itself and also are grinding their means around the racers, creating even more damage.

Thinking about wheel bearings are usually made from hardened steel, they can stand a significant amount of rotational abuse. However apply warm (through absence of lubrication) and water (busted seal) and all heck can break loose.

To replace a wheel bearing properly, it needs to be popped out of the hub setting up, preferably making use of a hydraulic press. Problems can develop with the re-installation of the new bearing, as the alignment needs to be exact to stay clear of the bearing breaking quickly as well as causing additional discomfort. Wheel bearings should last tens of hundreds of miles, yet numerous technicians will merely hammer the bearing back into the center assembly as opposed to specifically straightening it and using the previously mentioned press. This will inevitably bring about the bearing not turning in the vertical style that it was created for, speeding up wear and also damage to the part.

A lot of on-line parts stores will certainly now sell the whole hub assembly with the wheel bearing pressed into it, www.southernevolution.com.au, conserving the hassle and prospective extent for blunders within the certain bearing setting up.

If left to wear down additionally, a wheel bearing can confiscate as well as secure the axle, so believe carefully concerning your timing if the classic wheel bearing drone starts. Nevertheless, taking into consideration the forces that a drivetrain has to combat throughout its life time of usage, it is impressive how much time wheel bearings can last if put appropriately and also cared for.

Although it can be a labour-intensive task if one was to fall short, the shift to offering whole center assemblies should make a bad wheel bearing reparable from home, with a decent tool kit and also a bit of expertise. So do not stress the next time that ghastly whir starts to slip right into the cabin, as a fix might be only a ratchet spanner away.